Our Environmental Commitment!

Environmental stewardship is one of the founding principles of NEB. By promoting sound ecological practices and environmental sustainability, NEB ensures the protection and preservation of natural resources, both locally and globally. We continuously strive for improvement in our business processes in order to minimize and, where possible, mitigate our impact on the environment. Raising awareness of our duty to the environment is paramount to NEB’s corporate message. As an additional measure of their commitment, NEB has received ISO 14001 certification, a quality standard for environmental management systems.

Monarch® Nucleic Acid Purification Kits – Designed with sustainability in mind

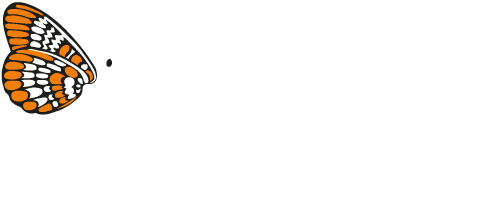

Eco-friendly & compostable shipping boxes!

We have gradually converted our shipping logistics for frozen and refrigerated goods for you: Instead of the usual polystyrene (“styrofoam”) insulation boxes, we now use sustainable and environmentally friendly shipping boxes with hemp/straw insulation, which require 50 times less energy in production.

Please dispose of cardboard with your local recycling program. Straw insulation panels are compostable and can be disposed of with your organic waste.

This environmentally friendly insulated box meets the strictest criteria for reliable and sustainable shipping:

Functional

shock-absorbing, moisture-regulating and very good insulating properties

Ecological

climate-neutral production in Germany from hemp/straw remnants

Pure

from pure and thermally treated hemp/straw fibres in food quality

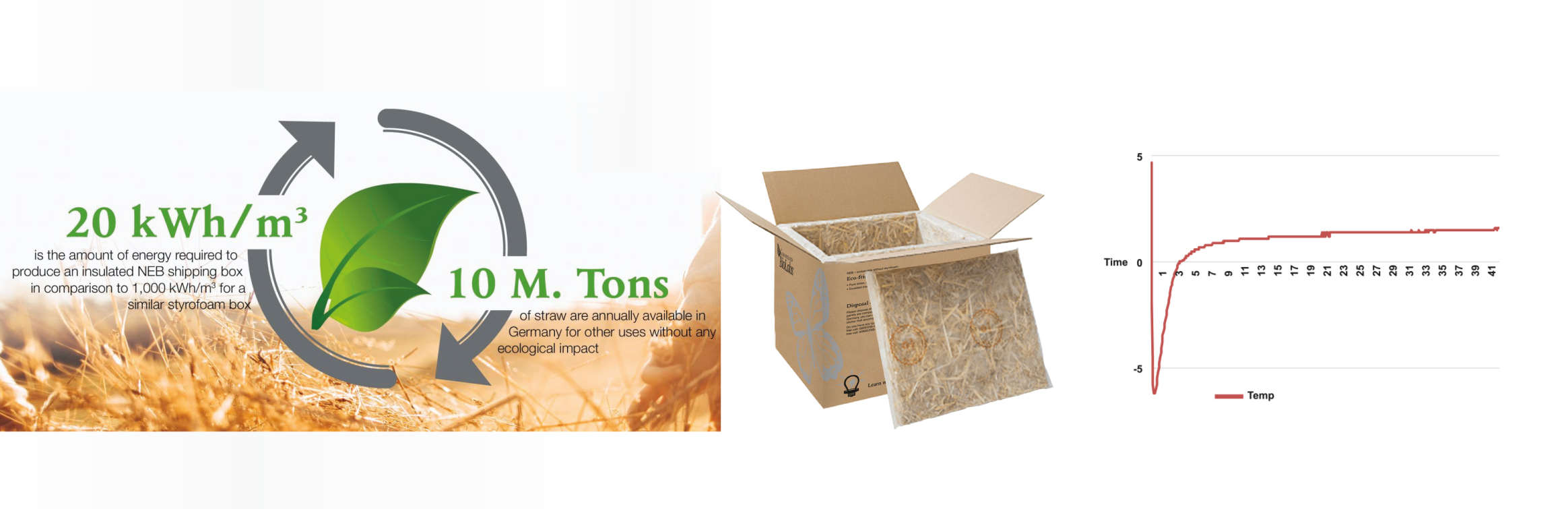

Tested

best insulation performance tested according to standards

Certified

tested and certified according to high hygienic standards

What our clients say

We have to support great

approaches like this.

Well done NEB!

Thank you!

Download our shipping policy!

Styrofoam-free packed

Green PE-Foil

100% recyclable and CO2

climate neutral

At New England Biolabs we send our customer magazine “NEB Expressions”, our catalogues or other special prints and brochures in protective “Green PE” foil – if possible bundled with several printed materials in one delivery.

The Green PE foil used is 100% recyclable and CO2 climate neutral, as it is not generated from fossil resources, but exclusively from renewable raw materials such as sugar and starch. Green PE is the only “eco-film” approved for shipping by Deutsche Post. If the Green PE foil is not recycled, it is completely decomposed into water and CO2 when thermally recycled.

What are the differences?

Bioplastics are a group of different plastics with very different properties. However, they must always meet at least one of two “bio” criteria.

Biobased

Biobased means that at least part of the plastic consists of renewable, i.e. vegetable raw materials, e.g. sugar, starch, oils, cellulose, etc.

Biodegradable

Biodegradable means that the plastic can be degraded by naturally occurring microorganisms. This produces water, CO2 and a small amount of biomass. Bio-based plastics can be biodegradable, but do not have to be.

Bioplastics:

Green PE foils (used by NEB) are bio-based and 100% recyclable, but not biodegradable. The raw material used is chemically identical to standard PE quality and therefore provides identical mechanical properties. However, since the raw material used for the production of the raw material is non-fossil (no crude oil), but bio-based and renewable (sugar, starch, cellulose…), Green PE film is much more sustainable than conventionally produced PE films. When used thermally, Green PE breaks down into water and CO2 without further residues.

Biodegradable foils

are bio-based and completely biodegradable under industrial composting conditions. The raw material used is PLA. The mechanical properties of biodegradable films are worse than those of PE or Green PE films. The modified raw material also gives the film an unmistakable optical and haptic “biofeeling”. For many applications, e.g. garbage bags, etc., the properties are absolutely sufficient, but not for use in postal dispatch.

Oxo-degradable is not “bio”.

Oxo-degradable or oxo-degradable plastics are often wrongly referred to as bioplastics. But they are anything but “bio”. Materials such as cobalt, manganese or iron are added to these plastics. Under the influence of UV light, heat and oxygen, the polymer chains are dissolved and the material decomposes into minute particles. In contrast to biodegradable plastics, however, there is no complete decomposition of the plastic by microorganisms. Although the plastic is no longer visible to the eye, it is still present and represents a major problem in our ecosystem in the form of microplastics. It is also foreseeable that oxo-degradable films will be banned in the EU due to their negative properties.

Climate neutral printing

NEB supports forest conversion measures and promotes the expansion of renewable energies.

For many years, NEB has been implementing CO2 climate-neutral production for our print products such as catalogs, brochures, or posters. With the help of our partner company “Climate Partner,” we calculate all the CO2 emissions that unavoidably occur in the process chain and offset them through recognized climate protection projects. In the past, we have supported projects for the protection of chimpanzees and gorillas in Central Africa, the establishment of wind and solar parks, as well as marine conservation efforts.

With the production of the 2023/24 catalog, we are supporting two projects: “Mountain Forest Project in Harz, Germany” (No. 1049) and “Clean Solar Energy for Three Indian States” (Project No. 1429). This way, we are supporting forest conversion measures and the promotion of habitat and species protection in Germany, as well as solar energy in India, which ultimately saves approximately 329,720 tons of CO2 per year by replacing electricity that would have otherwise been generated in thermal/fossil power plants.

Read the project details here:

1049 · Climate project + nature conservation

1429 · Solar energy